How Does R&D Manufacturing Power Smarter, Faster Growth?

May 2025

R&D in manufacturing isn’t just about inventing what’s next but about making it better, faster, and more efficient. When research and development are built into the manufacturing process, businesses unlock serious advantages: quicker product rollouts, streamlined operations, and smarter use of resources.

For industries like FMCG, food and beverage, and consumer goods, R&D-led manufacturing means more than clever concepts. It drives real outcomes, better formulations, improved packaging, reduced waste, and faster go-to-market. It’s where innovation stops being a slide deck and starts delivering ROI on the shop floor.

In this blog, we explore how R&D manufacturing helps you stay ahead of changing market demands, turn product ideas into reality, and grow without the usual bottlenecks.

Why Are R&D Tax Credits So Critical in Modern Manufacturing?

R&D is the backbone of modern manufacturing. It solves real-world challenges, fuels digital transformation, and makes innovation financially viable. Here’s how it’s driving smarter, faster growth on every factory floor.

1. It Solves Manufacturing’s Biggest Challenges

Manufacturing faces real pressure from net-zero demands to global competition, and R&D is where solutions take shape.

To qualify for manufacturing r&d costs tax relief, your work must tackle technical uncertainties and rethink how things are done. In manufacturing, that often means addressing challenges head-on:

- Net-zero targets: Developing low-carbon processes and materials that cut emissions without slowing production.

- Skills gaps: Automation and smart tech that bridge the talent shortage and boost efficiency.

- Low productivity: Upgrading outdated systems with robotics, AI, and software-driven workflows.

- Supply chain shocks: R&D helps build agile, resilient systems that can pivot under pressure.

- New regulations: Innovation enables businesses to evolve quickly and stay ahead of compliance shifts.

These aren’t just industry problems; they’re innovation triggers. And with R&D tax credits for manufacturing, tackling them makes business sense.

2. It Fuels the Shift to Industry 4.0

We’re not just upgrading products, we’re reinventing the way wider things are made. R&D is the engine behind Industry 4.0, where automation, data, and smart tech drive production.

Qualifying R&D often involves complex, non-obvious problem-solving. That could mean connecting IoT to your machines, using 3D printing for rapid testing, or building custom software, including accounting software, to improve performance.

R&D tax relief is the government’s way of backing smart risk. The more UK manufacturers embrace innovation, the faster we modernise the industry, making it leaner, greener, and ready for what’s next.

3. It Makes Innovation Affordable

Manufacturing innovation comes at a cost, and R&D tax relief makes it easier to fund.

Whether you’re scaling or pre-revenue, the incentive lets you recover part of your R&D spend, including:

- Staff time, NI, and pension contributions

- Software used in development

- Materials and consumables for testing

- Subcontractor or specialist support

- Relevant travel costs

This can be the green light for capital-intensive businesses to develop, test, and scale. More importantly, it reduces the financial risk of bold innovation and helps you move confidently.

Who Qualifies for R&D in Manufacturing?

It’s clear that R&D is a driving force behind manufacturing innovation, but who qualifies for it? The answer isn’t limited to scientists in lab coats. R&D eligibility spans multiple roles across your organisation, from the factory floor to the design studio.

Here’s a breakdown of the key contributors:

- Engineers & Designers: From mechanical and electrical engineers to software and materials engineers, these professionals are leaders in product design, development, and technical problem-solving.

- Scientists & Researchers: Focused on experimentation and scientific advancement, they help develop new materials, processes, or technologies that advance the industry.

- Technicians: Hands-on support who run tests, troubleshoot, and gather the data that underpins innovative progress.

- Project Managers & Team Leads: They steer R&D efforts, set timelines, allocate resources, and ensure projects move from concept to execution.

- Quality & Compliance Teams: Essential for ensuring new processes and products meet strict industry and regulatory standards.

- Production & Operations Teams: They’re the ones who trial, adopt, and implement R&D-driven changes in real-time manufacturing environments.

In short, R&D in manufacturing is a team effort, and if your business is solving technical challenges, chances are you’ve got qualifying activity across departments.

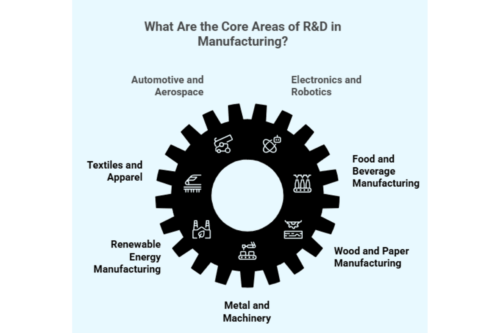

What Are the Core Areas of R&D in Manufacturing?

Research and development are no longer limited to traditional innovation labs. In modern manufacturing, R&D is embedded across sectors, driving operational improvements, sustainable practices, and product breakthroughs.

In fact, the UK’s total expenditure on R&D reached £49.97 billion in 2022, reflecting a 2.9% year-on-year increase, clear evidence of the sector’s growing commitment to innovation.

From food production to aerospace, businesses use R&D to challenge outdated systems, meet new regulations, and stay competitive in global markets.

Below is a look at the manufacturing sub-sectors where R&D plays a critical role:

1. Automotive and Aerospace

R&D in automotive and aerospace manufacturing is focused on making systems lighter, safer, and more efficient.

Companies in these sectors are:

- Developing advanced lightweight materials to improve fuel efficiency

- Engineering next-generation electric and hybrid vehicles

- Designing innovative safety systems and autonomous driving technologies

- Improving propulsion systems, avionics, and aerospace materials

- Enhancing satellite communication and military equipment

This kind of technical advancement meets regulatory pressure and enables manufacturers to reduce costs, improve safety, and bring new capabilities to market faster.

2. Electronics and Robotics

In electronics and robotics, R&D is central to increasing processing power, reducing energy consumption, and enhancing automation. In 2022 alone, UK electronics firms poured £7.9 billion into R&D, making up 16% of total business R&D spend. That’s not just investment; it’s momentum.

Key R&D efforts include:

- Designing more efficient microprocessors and semiconductors

- Experimenting with advanced display technologies such as OLED and quantum dots

- Developing smart devices and wearables with expanded functionality

- Streamlining manufacturing processes to reduce waste and environmental impact

As devices become more intelligent and integrated, manufacturers must continue to innovate to meet demand and differentiate in crowded markets.

3. Textiles and Apparel

R&D is redefining textiles from the fibre up. With changing consumer demands and environmental pressures, manufacturers are focused on:

- Developing performance fabrics with antimicrobial, moisture-wicking, or temperature-regulating properties

- Introducing sustainable production methods and low-impact dyeing techniques

- Innovating in smart textiles and wearable technology

- Advancing textile recycling and circular economy models

These innovations are helping apparel manufacturers respond to market shifts while improving material performance and environmental outcomes.

4. Food and Beverage Manufacturing

R&D in food and drink manufacturing is driving progress in production efficiency, food safety, and sustainability.

Manufacturers are investing in:

- New processing methods that improve product consistency and reduce energy use

- Preservation techniques that extend shelf life while maintaining nutritional value

- Sustainable packaging innovations to reduce plastic usage and meet compliance targets

- Novel ingredients and production techniques for plant-based and functional foods

R&D here is key to balancing regulatory compliance with shifting consumer trends and operational efficiency.

5. Renewable Energy Manufacturing

The renewable energy sector depends heavily on R&D to make clean energy scalable and cost-effective.

Key areas of innovation include:

- High-yield solar panels with improved energy conversion rates

- Advanced wind turbine designs that maximise power output and minimise maintenance

- Development of next-gen batteries and storage solutions

- Cost-effective production methods that reduce the manufacturing footprint of clean energy technologies

With global demand for renewables rising, manufacturers are using R&D to stay ahead of policy targets and infrastructure challenges.

6. Wood and Paper Manufacturing

Often seen as traditional, the wood and paper sector is undergoing significant change through R&D.

Current innovations focus on:

- Sustainable forestry practices and improved wood processing techniques

- High-efficiency paper production that reduces water and energy usage

- Bio-based materials as alternatives to plastic in packaging and construction

- New wood composites and engineered materials for industrial applications

These efforts are helping companies reduce environmental impact while meeting increasing demand for eco-friendly alternatives.

7. Metal and Machinery

As the backbone of industrial manufacturing, the metal and machinery sector relies on R&D to improve durability, precision, and automation. Ongoing initiatives include:

- Designing machinery with higher output and greater energy efficiency

- Creating advanced alloys tailored for specific performance conditions

- Introducing robotics and automation to speed up production lines

- Developing innovative metal treatment techniques to extend product lifespan

R&D in this sector is essential for increasing productivity and meeting construction, engineering, and heavy industry performance standards.

Ready to Claim R&D for Your Manufacturing Innovation?

If your team has invested time, talent, and capital into solving technical challenges, whether it’s new production methods, sustainability upgrades, or smarter systems, chances are you’re eligible for R&D tax relief.

At Accountancy Cloud, we specialise in helping manufacturers like you unlock the full value of innovation. From identifying eligible activities to navigating the new 2025 R&D scheme, we ensure your claim is not only compliant but fully optimised.

Here’s how we help:

- Accurately map technical work to claimable costs

- Maximise your return under the new merged R&D scheme

- Reduce risk by aligning your claim with HMRC expectations

- Provide end-to-end support from assessment to submission

Innovation deserves recognition and reward.

Let’s make sure you claim what you’re owed.

R&D Is How Manufacturing Moves Forward

The manufacturing industry stands at a pivotal point where innovation isn’t optional; it’s essential. Embracing R&D is no longer just about developing new products; it’s about improving processes, increasing efficiency, and staying competitive in a rapidly changing market.

With incentives like R&D tax relief available, investing in further innovation has never been more accessible, especially when the upcoming changes take effect in April. From sustainability to automation, R&D is helping manufacturers solve real challenges and unlock smarter, faster growth.

Businesses that actively invest in R&D are not just keeping up; they’re setting the pace for a more agile, sustainable, and future-ready manufacturing sector.

Frequently Asked Questions

What is the average cost of R&D in manufacturing?

The average cost of undertaking R&D in manufacturing can vary significantly depending on the scale of the project, the technological challenges being addressed, and the company's size. However, with manufacturing R&D tax credits, specifically the SME scheme and the Development Expenditure Credit, companies charged to UK corporation tax can reduce their corporation tax bill and receive significant financial returns, balancing overall expenditure.

How does R&D contribute to faster growth in manufacturing?

R&D drives growth in the manufacturing business sector by developing innovative solutions, technologies, and products. When combined with R&D tax credits and tax incentives, there’s a good chance the ability to innovate increases, thereby accelerating progress towards solutions that enhance productivity, efficiency, and cost-effectiveness.

Can small manufacturing companies afford extensive R&D?

Yes, even small manufacturing companies, or SMES (small and medium enterprises), can invest in extensive R&D in science for innovative projects. By qualifying for R&D tax relief claims, these smaller firms may secure tax benefits and financial incentives that could offset some of the initial costs of conducting R&D.

What are the recent major advancements in R&D for manufacturing?

R&D has triggered a cascade of advancements across several manufacturing fields. These include the development of efficient microprocessors, sustainable textile production methods, energy-efficient solar panel technologies, and pioneering machinery designs. Such advancements are significantly transforming the manufacturing landscape.

How does R&D influence global competition in manufacturing?

R&D encourages innovation, which leads to improved products, more efficient processes, and enhanced quality of goods. As such, new technologies support UK manufacturers in maintaining a competitive edge against lower-cost producers, thereby playing a pivotal role in influencing global competition.

Educational content just for startups. As a member, you’ll get unlimited access to an extensive range of guides, blogs and advice to help you run and grow your business.